Form Cut pivots and expands at Tonsley

The COVID-19 pandemic has certainly bought its challenges to the business community across the country, however this adversity has brought with it innovation for those who sought to meet the changing needs of our country, and the world.

Local Adelaide business Form Cut, owned by father and son Joe and Karl Falzon, was a defence focused organisation that developed packaging, handling, and storage solutions for the safe and secure transit of defence materials.

During the pandemic they swung into action, reviewing their production capabilities and retooling so they could produce much needed PPE for essential workers such as nurses, GPs, ICU doctors, aged care workers, and more.

The team at Form Cut moved quickly during the pandemic, and found that their company premises in Lonsdale did not meet with the requirements for the production of the face shields, which are considered medical devices listed with the Therapeutic Goods Authority (TGA).

When Karl reached out to the team at Tonsley to assist with finding suitable premises, quick work was undertaken to identify a suitable tenancy within the innovation district, and preparing the space within a three week period to move the business in during May 2020.

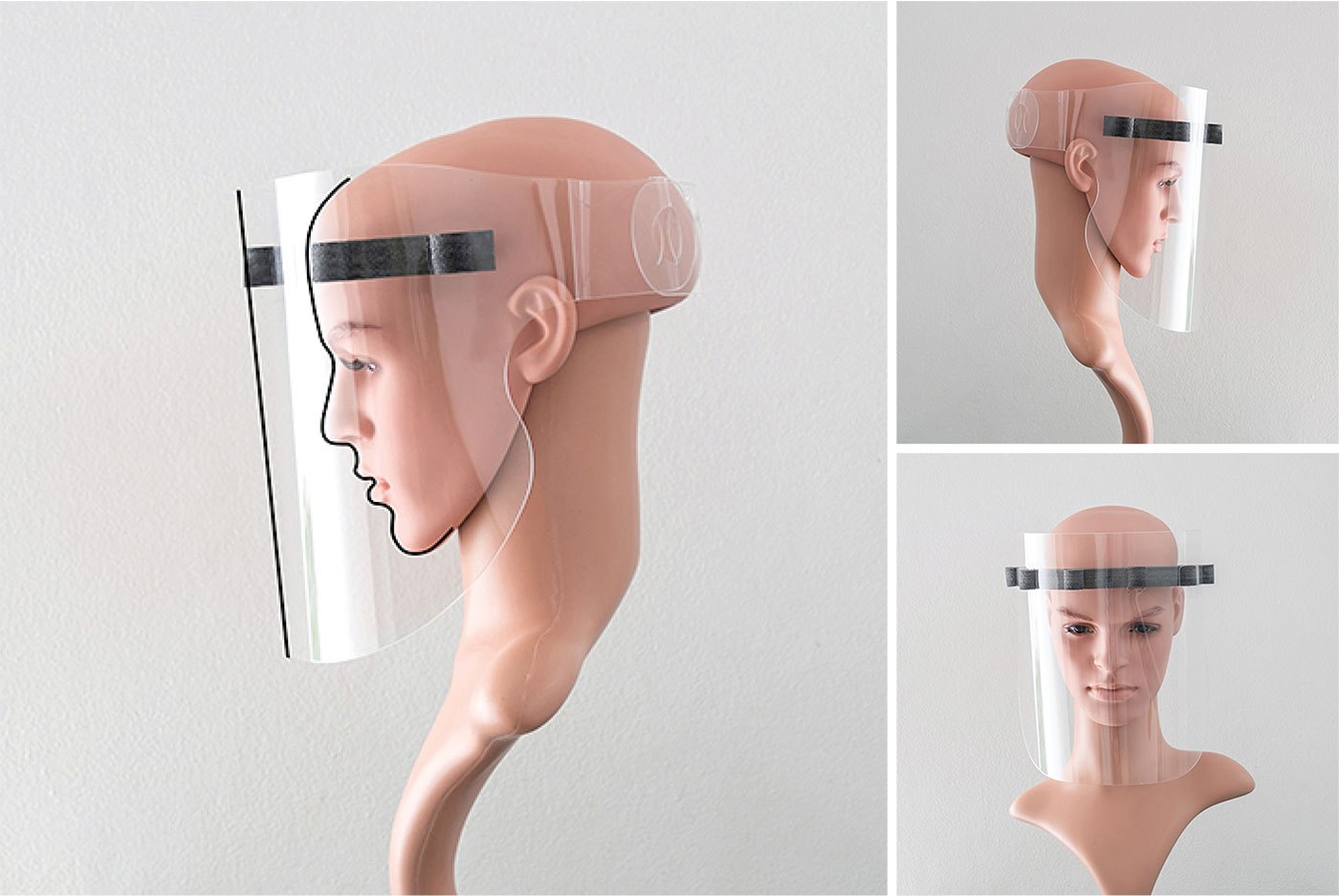

The VForm Face Shield (Credit: Form Cut)

Initially production began at some 2,500 VForm Face Shields per day, with quick moves to a surge capacity of 4,000 per day with thanks to orders from SA Health to ensure that immediate demand for these face shields was met in South Australian hospitals.

Currently fulfilling orders from a medical device supplier and three local GP clinics in Adelaide, Form Cut is also now receiving inquiries from major government agencies across Australia.

This demand has offered excellent opportunities for the family-owned business and has meant a need to expand their current Tonsley facility.

Their expanded premises within Tonsley Innovation District will not only allow for improved processes in the business, but it will also provide a space for their staff to continue all-important research and development.

Form Cut are currently investigating how they can manufacture new products made from the ‘scrap material’ used in the face shield manufacturing process.

Driven by lateral thinking, hands-on agility and a desire to help protect people during the global health crisis, Tonsley innovators such as Form Cut Australia have responded to the COVID-19 crisis with products needed by government agencies, not for profit organisations and private businesses.

To join our community of innovators, check out our commercial accommodation options and see if your business is a fit for Tonsley Innovation District.

Stay up to date with the latest news, developments events and activities at Tonsley Innovation District