Manufacturer moves to Tonsley to make face shields

Health, medical devices and assistive technologies is one of four focus sectors at Tonsley, which has been boosted by the arrival of specialist industrial design and manufacturing company Form Cut Australia.

The company recently made the move to Tonsley so that it could start manufacturing much needed PPE for essential workers in the battle against COVID-19.

Owned by father and son Joe and Karl Falzon, Form Cut Australia has retooled to help ensure Australia has enough PPE supplies to protect frontline healthcare workers during the pandemic.

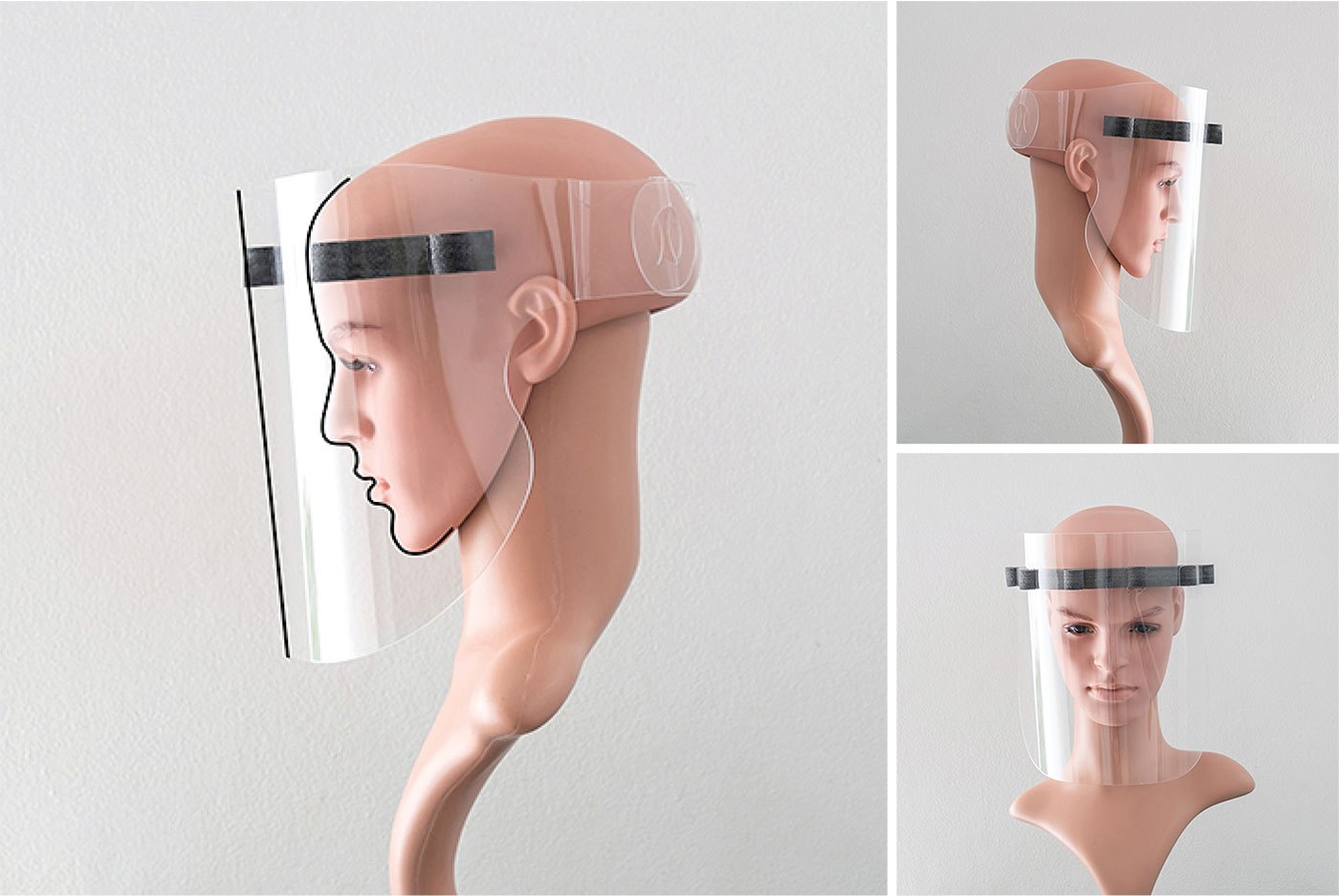

Mainly producing specialist packaging products for defence and healthcare, Form Cut has made a significant and timely diversification and drawn on Karl’s skills as an industrial designer to create four versions of face shields. These have been designed to suit the needs of healthcare personnel, including surgeons, ICU doctors and nurses, paramedics, GPs and their staff, and for workers in aged and disability care.

The company’s premises at Lonsdale did not meet requirements for production of medical devices listed with the Therapeutic Goods Authority (TGA). So the Tonsley team responded to Karl’s request for suitable premises, identifying a tenancy in the Administration Building adjacent to South Road, then pushing through the paperwork and making the tenancy ready in three weeks.

"“Tonsley is a great fit for the direction that we want to take Form Cut Australia. We are looking at moving our entire operation here.”"

Karl Falzon, CEO Form Cut Australia

In barely two months, Karl and his team identified the potential to produce face shields, designed them, set up at Tonsley, sourced machinery and materials, and begun producing the devices to exacting TGA standards. They are now fulfilling orders from a medical device supplier and three local GP clinics, with more inquiries coming from major government agencies and medical practices across Australia.

Established in 1999, Form Cut is an integrated design-led manufacturer that collaborates internationally and competitively supplies products to all mainland states and capital cities. Certified through SAI Global to the ISO 9001:2015 Quality Management System, it has a specialist team of industrial designers and engineers who deliver custom, protective packaging solutions for military use, incorporating shock and vibration attenuation for fragile and sensitive products, thermal and acoustic insulation and linings, seals, gaskets, sub-assemblies, occupant protection systems and a growing range of its own product lines.

To join over 1,700 innovators like Joe and Karl Falzon of Form Cut at Tonsley Innovation District, check out our our range of commercial accommodation options.

Stay up to date with the latest news, developments events and activities at Tonsley Innovation District