Robotics company enjoys new taste of success after moving to tonsley innovation district

Tonsley Innovation District-based automation company Accurate Dosing Systems (ADS) has landed a key contract with the world’s largest privately-owned fragrance and taste company, Firmenich, to supply and service a purpose-built robot for its creation lab in Belgium.

The high-tech robot will automate the process of accurately measuring out hundreds of flavouring solutions, which go on to determine the taste profile of food and beverages such as soups, coffee, yogurt and breakfast cereals.

Products developed by Firmenich, which is headquartered in Switzerland, reach more than four billion consumers a day, in more than 100 markets globally, across both its Perfumery and Taste & Beyond business divisions.

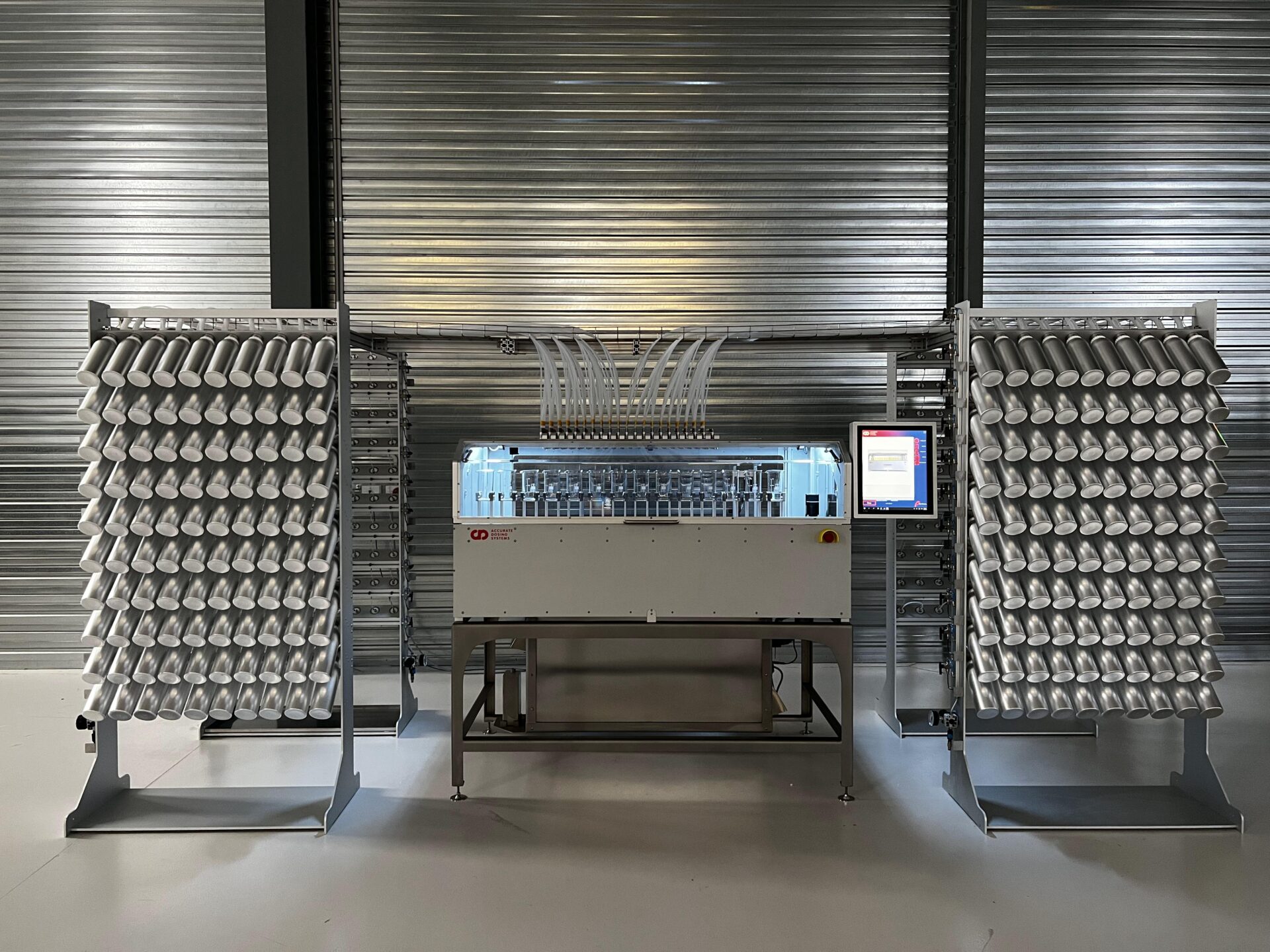

The Tonsley-built robot will include hybrid technology, combining two different methods of dosing that ultimately achieve faster speeds and a higher automation rate.

ADS co-founder and Managing Director Masoud Bahmai said his business was one of just five companies in the world offering the specialised dosing technology, allowing scent and flavour formulas to be compounded on the machine in minutes instead of hours – a game changer for the $24 billion (USD) industry.

“The hybrid technology will be the first dosing robot in Taste & Beyond – Firmenich’s flavour division,” Mr Bahmai said. “Usually our competitors do either gravimetric or volumetric dosing but by offering an optimised combination we can now meet the demands of mid-to-large-size operations that often need speed [of processing] and high automation rates.”

The hybrid robot – scheduled to be shipped to Belgium later this year – is also expected to reduce Firmenich’s use of plastic pipettes during its trial and testing phase.

One of Accurate Dosing Systems’ industry-leading hybrid dosing robots which has the capacity to compound scent and flavour formulas in minutes instead of hours.

“As a part of our ongoing commitment to sustainability and ambitious ESG commitments on nature and climate, we are constantly striving for ways to reduce our environmental impact. We are dedicated to deriving the best from nature sustainably,” Annemarie Steffl VP Eurotech Taste & Beyond at Firmenich said. “This new digitalised dosing system will allow us to achieve an even greater level of precision, efficiency and speed, while eliminating raw materials waste and enhance our ability to provide precise value chain data to our customers.”

Mr Bahmai said enhanced brand visibility since relocating to Tonsley had delivered immediate benefit.

“Being a young business can sometimes be a disadvantage when dealing with larger corporate companies because they are often more comfortable being serviced by bigger, established companies. But being at Tonsley they see that we have the support of a whole community. That image is quite powerful to outsiders,” he said. A shift in acceptance around remote servicing and connectivity since the pandemic is also playing to ADS’s advantage.

"Companies were sometimes concerned they couldn’t receive the service support required from Australia but now, the whole paradigm has changed. Three of our last four sales have been to clients in Europe. It's getting easier for Australian businesses to export and provide services from here, so I think we’re going to see a lot more, low volume, high value-added manufacturing coming out of here."

Industrial engineer Masoud Bahmai, the Managing Director of Accurate Dosing Systems

Accurate Dosing Systems’ skilled workforce training at its Tonsley headquarters.

Since moving to Tonsley, ADS has tapped into the extensive advanced manufacturing expertise that exists within the district to elevate its approach to robotics, including purchasing equipment from Phoenix Contact and Rockwell Automation. It has also engaged 3D printing services from Flinders University for some of its components.

“We are in the right place,” Mr Bahmai said. “We are surrounded by manufacturing technology companies, so it’s easier for us to attract staff with higher skills compared to [our previous premises] in Lonsdale because it’s a more vibrant and exciting environment with opportunities for collaboration.

“We also have a couple of Flinders University students working for us part time, so they can pop in after their classes, and there’s easy access to the train station.”

Minister for Housing and Urban Development Nick Champion said, once more, Tonsley’s innovation ecosystem was delivering a favourable environment for long-term growth, job creation, technological advancement, and increased commercial success.

An advanced level of Programmable Logic Controller software has been installed in ADS’ dosing robots, which plays a critical role in its ability to automate, improve efficiency and reduce downtime.

“It’s great to see this local company now using the Precinct’s collaborative connections, entrepreneurial culture and global networks to expand its influence and reach around the world,” Minister Champion said. “This new partnership is another success story of tech commercialisation and again shows why South Australia is a smart place to invest.”

Accurate Dosing System’s Tonsley factory has the capacity to manufacture dozens of robots a year. Moving forward, Mr Bahmai said he hoped to provide his products and services to hundreds of flavour and fragrance factories and creation laboratories across the globe.

“Ultimately, we want to provide a really good service model to work very closely with our clients and make sure that we take good care of them,” he said.

Stay up to date with the latest news, developments events and activities at Tonsley Innovation District